World's smallest class

Ultra-Compact Vacuum Reflow Furnace

Ultra-Compact Vacuum Reflow Furnace

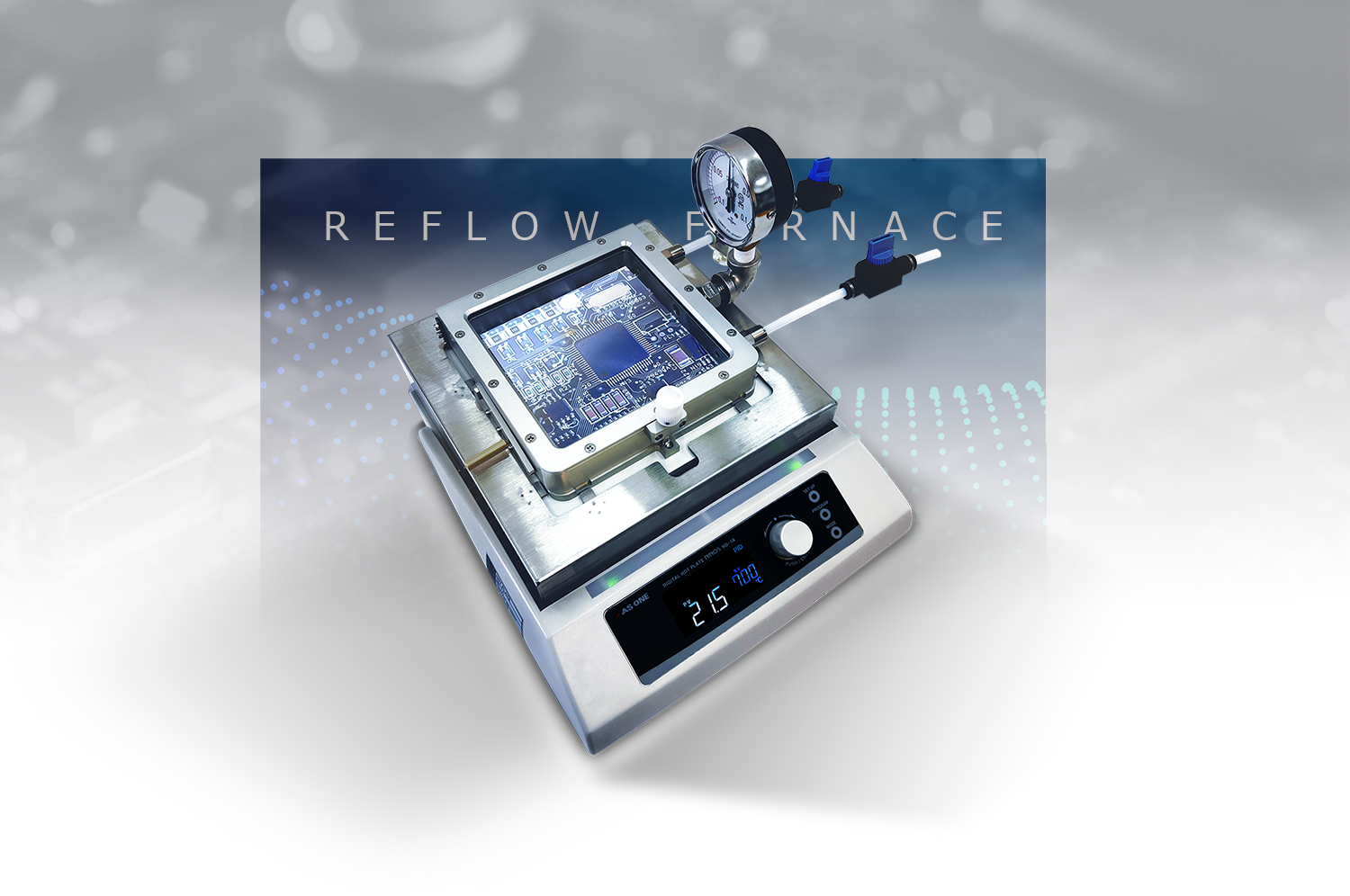

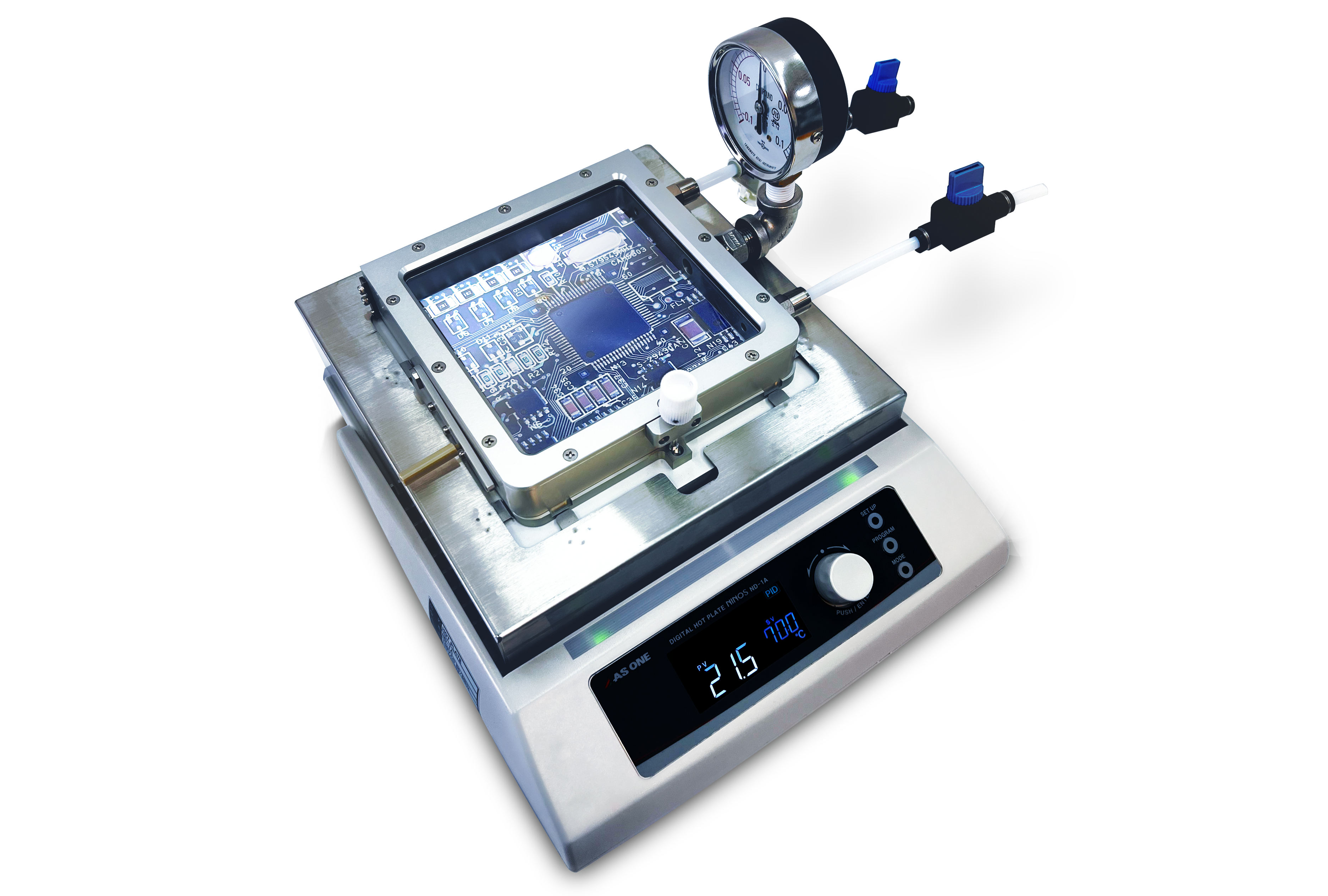

It is a reflow furnace with a super compact design specialized for prototyping and development while also enabling vacuum and nitrogen purging.

It allows for easy reflow anywhere, anytime, without being restricted by space constraints.

Advantages

♦Lightweight and a compact design

With its ultra-compact and ultra-lightweight design measuring W320mm×D360mm×H138mm.

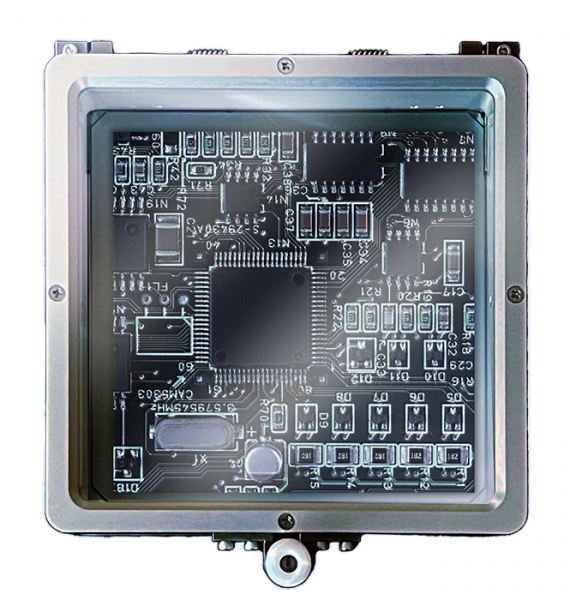

♦Monitor the progress of reflow through the glass lid.

You can reflow while observing the condition of the substrate (sample), allowing you to work with peace of mind.

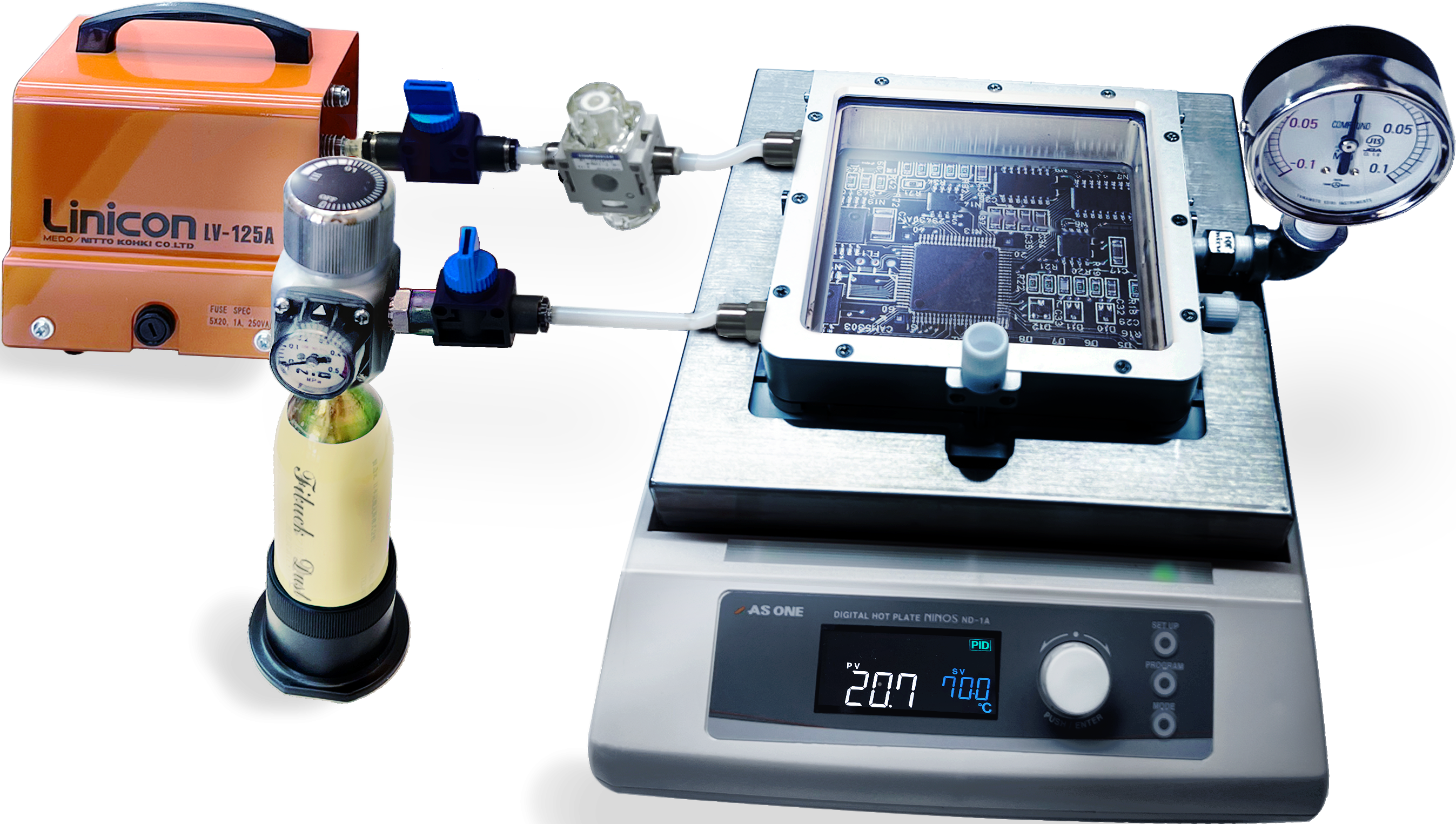

♦Vacuum and nitrogen purging possible (*1)

Has capability for vacuum and nitrogen purging, enabling reflow without the occurrence of solder balls or voids.

(*During cooling, loosening the lock while flowing nitrogen (air) allows for faster temperature reduction.)

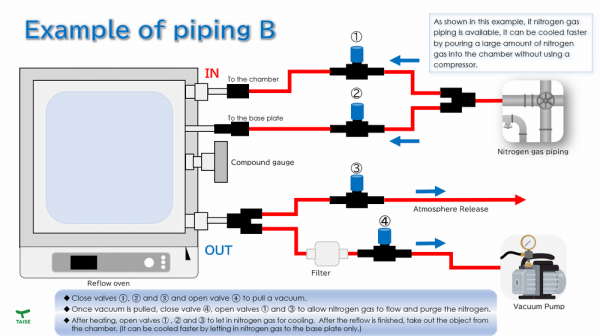

Notice: The equipment includes nitrogen cylinder cartridges. Although the equipment can be exported internationally, the nitrogen cylinder cartridges are for domestic use within Japan only. If N2 piping equipment is available, the same configuration can be applied.

♦High temperature control accuracy with PID control.

Effective control within ±1°C is possible through PID control.

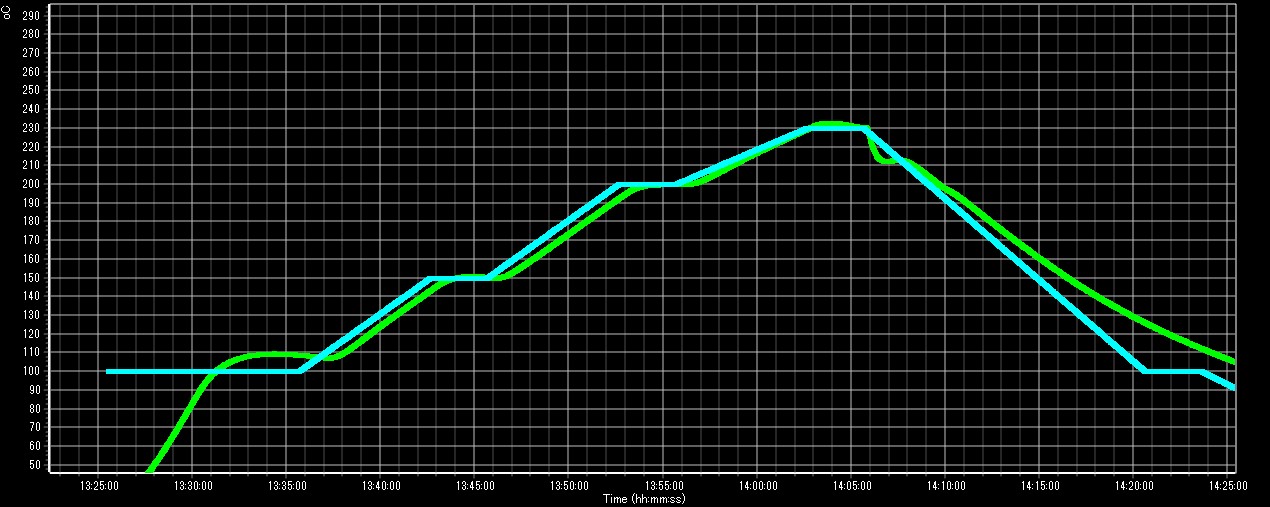

♦Temperature profile setting possible (*2)

Temperature profile setting is possible using the program function of the hot plate (up to 8 steps).

(*Due to the heating capacity of the built-in heater in the hot plate, there may be instances where the temperature does not rise according to the set program. Approx. 7-8°C/min)

♦Temperature status can be output to PC (*2)

Enable output of the temperature profile graph and current temperature status to a PC.

Dedicated software included (CD-ROM, DL).

*1:TR-20 S-125V *2:TR-125V2

♦Customization available

We can accommodate customization according to your specifications.

Honored to receive this certificate from the Governor of Chiba on December 23, 2022."

Our product has received recognition by the Chiba Prefectural Government with the "Manufacturing Certification Award“.

Taise's Reflow Furnace in the Media Spotlight at SEMICON JAPAN.

Reflow Furnace Specifications Table

| TRF Series | |||||||||

|---|---|---|---|---|---|---|---|---|---|

|

furnace main unit only |

Model Number | Standard | Vacuum | ||||||

| TRF-95 | TRF-125 | TRF-125V | |||||||

|

|

|

|||||||

| Dimensions(mm) | W110×D127×H27 | W140×D157×H27 | W145×D153×H32 | ||||||

| Internal dimensions(mm) | W95×D95×H15 | W125×D125×H15 | W116×D116×H16 | ||||||

| Weight | less than 350g | less than 350g | less than 350g | ||||||

| Lid operation method |

spring-loaded opening/closing system |

Arm fixed Angle:35°、45°、55° |

|||||||

| Material | Body: Aluminum Handle: Teflon Window panel: Heat-resistant glass | ||||||||

*1 Temperature controller(Dimensions:W85×D170×H103mm Weight:0.9kg) is excluded.

*2 The equipment can be exported internationally, the nitrogen cylinder cartridges are for domestic use within Japan only. If N2 piping equipment is available, the same configuration can be applied.

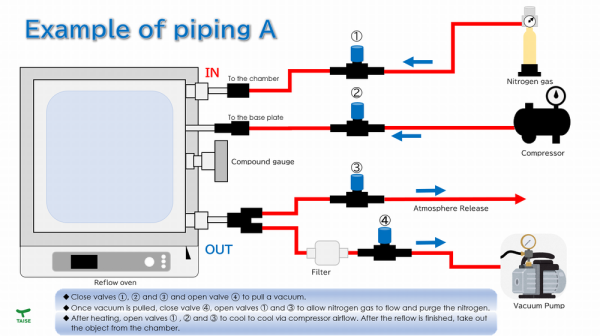

♦Reflow Furnace piping utilization examples.

Example of piping [PDF形式/330.18KB]

《Background》

Traditional desktoptop reflow furnaces are often large in size, limiting the places where they can be used.

Many customers who do not have their own reflow furnace have to outsource their work, resulting in significant time and expenses.

Furthermore, we received numerous requests from customers for a more basic and affordable model without multifunctional or high-performance features.

Considering the trend of miniaturization in electronic components, we recognized the need for smaller reflow furnaces.

Additionally, we observed a gap in the market for a product that offers minimal functionality at an affordable price, making reflow accessible to everyone. Hence, we developed the desktoptop ultra-compact vacuum reflow furnace.

Our desktoptop ultra-compact vacuum reflow furnace is among the smallest in the World ( our research).

It enables reflow in a convenient and accessible manner for anyone, anywhere.

Our product is suitable for those who are new to reflow or those who find it inconvenient to use larger, high-performance reflow furnaces.

We are proud to announce that our product has received recognition from the Chiba Prefectural Government with the “ Manufacturing Certification Award “.

For businesses, the benefits of adopting our desktoptop ultra-compact vacuum reflow furnace include the ability to perform reflow in-house, leading to significant time and cost savings. This, in turn, accelerates product development and increases profit margins by reducing running costs.

By enabling in-house reflow, significant time reduction and cost savings is achievable, leading to faster development and better profit margins.

For those new to reflow or those who already own a reflow furnace but are interested in smaller models, please feel free to contact us. (info(@)e-taise.co.jp)

*Please remove ( ) from this email address before submitting.

We will respond to inquiries via email. Please note that the reply may take several days depending on the subject to the inquiry details.

Click Here for the Catalogue